Shaft Glands :

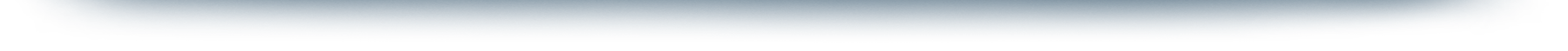

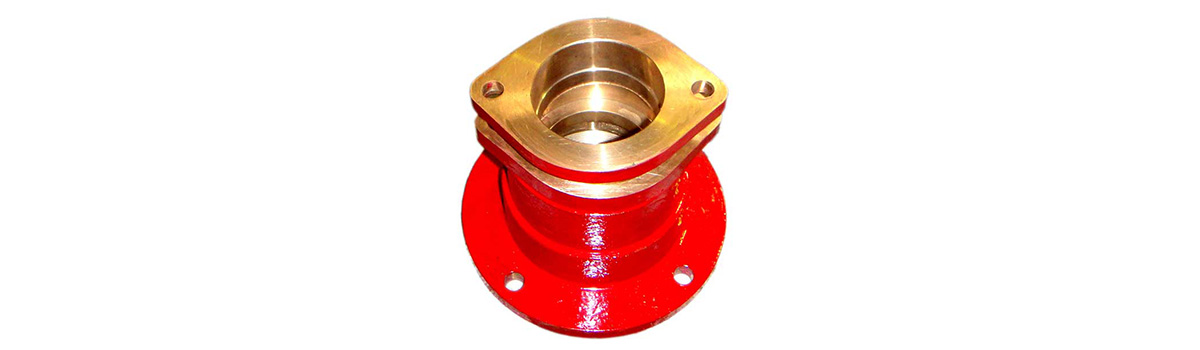

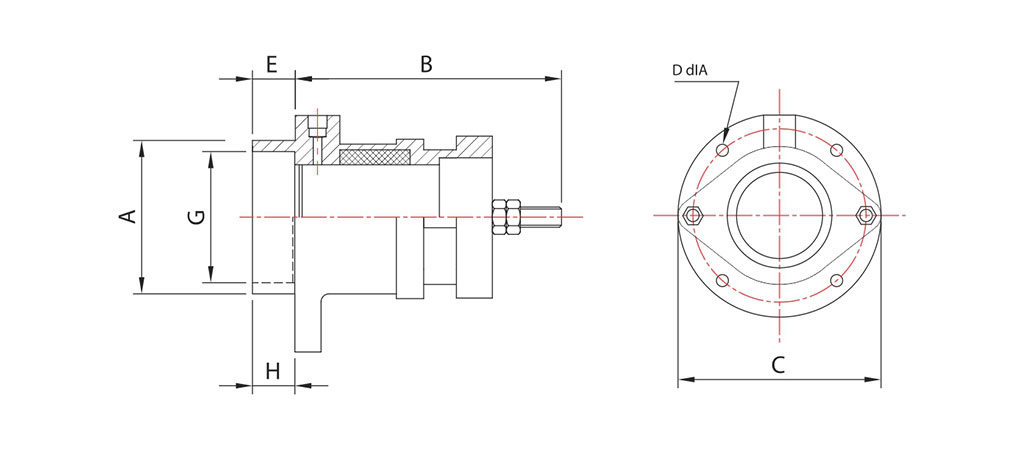

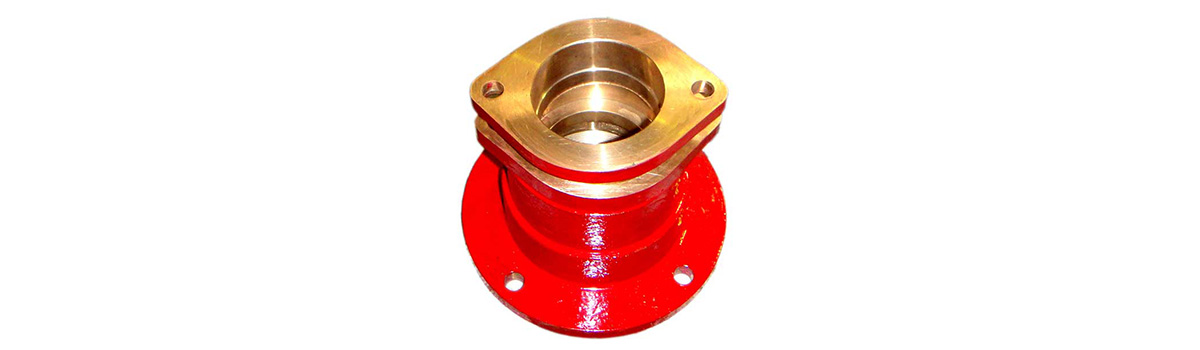

Water Lubricated Gland

The water lubricated gland is used where an intermediate bearing is required on the inboard end of the stern tube. It is used as intermediate bearing between the 'P' bracket and the gearbox as well as forming a watertight seal at the point where propeller shaft enters the hull. The gland is casted from gunmetal and is fitted with a half length water lubricated bearing.

Imperial

| CODE |

SHAFT |

A |

B |

C |

D |

E |

PCD |

G |

H |

| FWII 100 |

1.00 |

1.63 |

3.50 |

3.50 |

0.406 |

2.75 |

2.75 |

1.3/8”X12TPI |

1.00 |

| FWII 125 |

1.25 |

2.25 |

5.13 |

4.50 |

0.406 |

3.13 |

3.75 |

1.1/2”BSP |

1.00 |

| FWII 150 |

1.50 |

2.75 |

5.25 |

4.50 |

0.406 |

3.50 |

3.75 |

2.000"BSP |

1.00 |

| FWII 175 |

1.75 |

2.75 |

5.30 |

4.75 |

0.406 |

4.00 |

4.00 |

2.000"BSP |

1.00 |

| FWII 200 |

1.625 |

3.50 |

6.50 |

5.75 |

0.531 |

4.75 |

4.75 |

2.1/2"BSP |

1.25 |

| FWII 225 |

2.00 |

3.50 |

6.50 |

5.75 |

0.531 |

5.25 |

4.75 |

2.1/2"BSP |

1.25 |

| FWII 250 |

2.25 |

4.00 |

7.25 |

6.25 |

0.531 |

6.00 |

5.25 |

3.000"BSP |

1.25 |

| FWII 275 |

2.50 |

4.38 |

7.84 |

7.00 |

0.531 |

6.66 |

6.00 |

3.000"BSP |

1.50 |

Metric

| CODE |

SHAFT |

A |

B |

C |

D |

E |

PCD |

G |

H |

| FWIM 025 |

25 |

41.0 |

89 |

89 |

10.3 |

70 |

2.75 |

1.3/8”X12TPI |

25 |

| FWIM 030 |

30 |

57.2 |

130 |

114 |

10.3 |

80 |

3.75 |

1.1/2”BSP |

25 |

| FWIM 035 |

35 |

70.0 |

133 |

114 |

10.3 |

80 |

3.75 |

2.000"BSP |

25 |

| FWIM 040 |

40 |

70.0 |

133 |

114 |

10.3 |

89 |

4.00 |

2.000"BSP |

25 |

| FWIM 045 |

45 |

70.0 |

135 |

120 |

13.5 |

102 |

102 |

2.1/2"BSP |

25 |

| FWIM 050 |

50 |

89.0 |

165 |

146 |

13.5 |

121 |

121 |

2.1/2"BSP |

32 |

| FWIM 055 |

55 |

89.0 |

165 |

146 |

13.5 |

133 |

121 |

2.1/2"BSP |

32 |

| FWIM 060 |

60 |

102.0 |

185 |

159 |

13.5 |

152 |

133 |

3.000"BSP |

32 |

| FWIM 070 |

70 |

111.0 |

200 |

159 |

13.5 |

170 |

152 |

3.000"BSP |

44 |

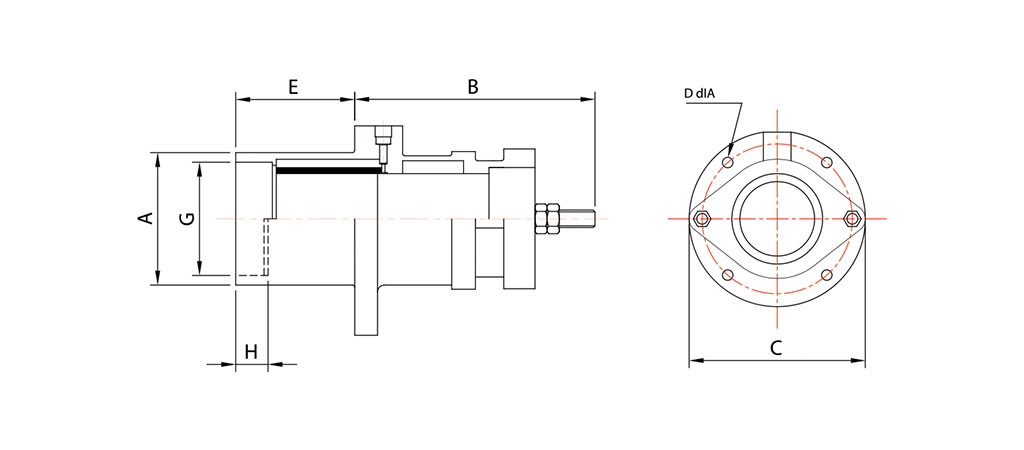

Inboard Flexible Gland:

This type of gland is usually employed in installations where its position is very close to the half coupling connecting the shaft to the gearbox. This type of gland is used where the engine is not flexibly mounted. The flexible gland assembly is manufactured in gunmetal LG2 and is supplied completely with a heavy duty flexible hose end stainless steel clamps.

Imperial

| CODE |

SHAFT |

A |

B |

C |

D |

E |

PCD |

G |

H |

| FWII 125 |

1.25 |

2.25 |

7.75 |

4.50 |

0.406 |

0.63 |

3.75 |

1.1/2”BSP |

1.00 |

| FWII 150 |

1.50 |

2.63 |

7.75 |

4.50 |

0.406 |

0.63 |

3.75 |

2.000"BSP |

0.88 |

| FWII 175 |

1.75 |

2.88 |

8.06 |

4.75 |

0.406 |

0.63 |

4.00 |

2.000"BSP |

1.00 |

| FWII 200 |

2.00 |

3.88 |

9.63 |

5.75 |

0.531 |

1.00 |

4.63 |

2.1/2"BSP |

1.00 |

| FWII 225 |

2.25 |

4.00 |

10.00 |

6.00 |

0.531 |

1.00 |

4.88 |

2.1/2"BSP |

1.25 |

| FWII 250 |

2.50 |

4.00 |

10.00 |

6.00 |

0.531 |

1.00 |

4.88 |

3.000"BSP |

1.25 |

Metric

| CODE |

SHAFT |

A |

B |

C |

D |

E |

PCD |

G |

H |

| FWIM 030 |

30 |

57.2 |

197 |

114 |

10.3 |

16 |

95 |

1.1/2”BSP |

25 |

| FWIM 035 |

35 |

66.8 |

197 |

114 |

10.3 |

16 |

95 |

2.000"BSP |

25 |

| FWIM 040 |

40 |

66.8 |

197 |

114 |

10.3 |

16 |

95 |

2.000"BSP |

25 |

| FWIM 045 |

45 |

73.2 |

205 |

120 |

10.5 |

16 |

102 |

2.000"BSP |

25 |

| FWIM 050 |

50 |

85.9 |

245 |

146 |

13.5 |

25 |

118 |

2.1/2"BSP |

25 |

| FWIM 055 |

55 |

101.6 |

245 |

152 |

13.5 |

25 |

124 |

2.1/2"BSP |

32 |

| FWIM 060 |

60 |

101.6 |

245 |

152 |

13.5 |

25 |

124 |

3.000"BSP |

32 |

Grease Lubricated Gland:

The grease lubricated gland is a main support bearing for the shaft and is used where a bearing is required on the inboard end of the stern tube. It can also be used as a shaft strut and gearbox. The gland is manufactured from gunmetal LG2. It is lubricated by grease by injecting grease into grease ways.

Imperial

| CODE |

SHAFT |

A |

B |

C |

D |

E |

PCD |

G |

H |

| FWII 100 |

1.00 |

1.63 |

3.50 |

3.50 |

0.406 |

0.63 |

2.75 |

1.3/8”X12TPI |

0.75 |

| FWII 125 |

1.25 |

2.25 |

5.38 |

4.50 |

0.406 |

1.00 |

3.75 |

1.1/2”BSP |

1.00 |

| FWII 150 |

1.50 |

2.63 |

5.38 |

4.50 |

0.406 |

1.00 |

3.75 |

2.000"BSP |

1.00 |

| FWII 175 |

1.75 |

2.75 |

5.88 |

4.75 |

0.406 |

1.00 |

4.00 |

2.000"BSP |

1.00 |

| FWII 200 |

1.625 |

3.38 |

7.63/td>

| 5.75 |

0.531 |

1.25 |

4.75 |

2.1/2"BSP |

1.25 |

| FWII 225 |

2.25 |

3.38 |

7.63 |

5.75 |

0.531 |

1.25 |

4.75 |

2.1/2"BSP |

1.25 |

| FWII 250 |

2.50 |

4.00 |

7.50 |

6.25 |

0.531 |

1.25 |

5.25 |

3.000"BSP |

1.25 |

| FWII 275 |

2.75 |

4.00 |

7.88 |

7.00 |

0.531 |

1.50 |

6.00 |

3.000"BSP |

1.50 |

Metric

| CODE |

SHAFT |

A |

B |

C |

D |

E |

PCD |

G |

H |

| FWIM 025 |

25 |

41.0 |

89 |

89 |

10.3 |

70 |

70 |

1.3/8”X12TPI |

25 |

| FWIM 030 |

30 |

57.2 |

130 |

114 |

10.3 |

80 |

95 |

1.1/2”BSP |

25 |

| FWIM 035 |

35 |

70.0 |

133 |

114 |

10.3 |

80 |

95 |

2.000"BSP |

25 |

| FWIM 040 |

40 |

70.0 |

133 |

114 |

10.3 |

89 |

95 |

2.000"BSP |

25 |

| FWIM 045 |

45 |

70.0 |

135 |

120 |

13.5 |

102 |

102 |

2.000"BSP |

25 |

| FWIM 050 |

50 |

89.0 |

165 |

146 |

13.5 |

121 |

121 |

2.1/2"BSP |

32 |

| FWIM 055 |

55 |

89.0 |

165 |

146 |

13.5 |

133 |

121 |

2.1/2"BSP |

32 |

| FWIM 060 |

60 |

102.0 |

185 |

159 |

13.5 |

152 |

133 |

3.000"BSP |

32 |

| FWIM 070 |

70 |

111.0 |

200 |

159 |

13.5 |

170 |

152 |

3.000"BSP |

44 |