Accessories

(Our High Quality Propulsion System is Manufactured as per UK/EU Standards)

Cone Nuts

MATERIAL - MANGANESE BRONZE BS1400 HTB1

| CONE NUT CODE |

IMPERIAL

SHAFT DIA |

METRICSHAFT

DIATHREAD |

A |

B |

C |

D |

| CNMG014 |

¾ |

20 |

M14 x 12 |

36.5 |

22 |

35 |

| CNMG016 |

1.0 |

25 |

M16 x 2 |

38.0 |

24 |

38 |

| CNMG020 |

1.1/4 |

30 |

M20 x 2.5 |

47.0 |

30 |

48 |

| CNMG024 |

1.1/2 |

35 |

M24 x 3 |

48.5 |

36 |

54 |

| CNMG025 |

1.5/8 |

40 |

M24 x 3 |

61.0 |

36 |

60 |

| CNMG030 |

1.3/4 |

45 |

M30 x 3 |

61.0 |

46 |

60 |

| CNMG031 |

1.3/4 |

45 |

M30 x 3 |

76.0 |

46 |

70 |

| CNMG036 |

2.0 |

50 |

M36 x 3 |

76.0 |

55 |

70 |

| CNMG037 |

2.1/4 |

55 |

M36 x 3 |

88.0 |

55 |

85 |

| CNMG042 |

2.1/2 |

60 |

M42 x 3 |

88.0 |

65 |

85 |

| CNMG043 |

2.1/2 |

60 |

M42 x 3 |

89.0 |

65 |

98 |

| CNMG048 |

2.3/4 |

70 |

M48 x 3 |

89.0 |

75 |

98 |

| CNMG049 |

2.3/4 |

70 |

M48 x 3 |

100.0 |

75 |

115 |

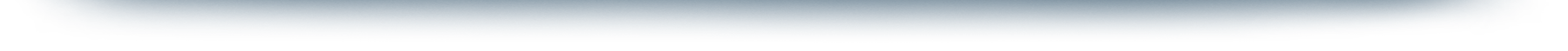

Tab Washers

MATERIAL - MANGANESE BRONZE BS1400 HTB1

| CONE NUT CODE |

IMPERIAL

SHAFT DIA |

METRICSHAFT

DIATHREAD |

A |

B |

C |

D |

| CNMG014 |

¾ |

20 |

M14 x 12 |

36.5 |

22 |

35 |

| CNMG016 |

1.0 |

25 |

M16 x 2 |

38.0 |

24 |

38 |

| CNMG020 |

1.1/4 |

30 |

M20 x 2.5 |

47.0 |

30 |

48 |

| CNMG024 |

1.1/2 |

35 |

M24 x 3 |

48.5 |

36 |

54 |

| CNMG025 |

1.5/8 |

40 |

M24 x 3 |

61.0 |

36 |

60 |

| CNMG030 |

1.3/4 |

45 |

M30 x 3 |

61.0 |

46 |

60 |

| CNMG031 |

1.3/4 |

45 |

M30 x 3 |

76.0 |

46 |

70 |

| CNMG036 |

2.0 |

50 |

M36 x 3 |

76.0 |

55 |

70 |

| CNMG037 |

2.1/4 |

55 |

M36 x 3 |

88.0 |

55 |

85 |

| CNMG042 |

2.1/2 |

60 |

M42 x 3 |

88.0 |

65 |

85 |

| CNMG043 |

2.1/2 |

60 |

M42 x 3 |

89.0 |

65 |

98 |

| CNMG048 |

2.3/4 |

70 |

M48 x 3 |

89.0 |

75 |

98 |

| CNMG049 |

2.3/4 |

70 |

M48 x 3 |

100.0 |

75 |

115 |

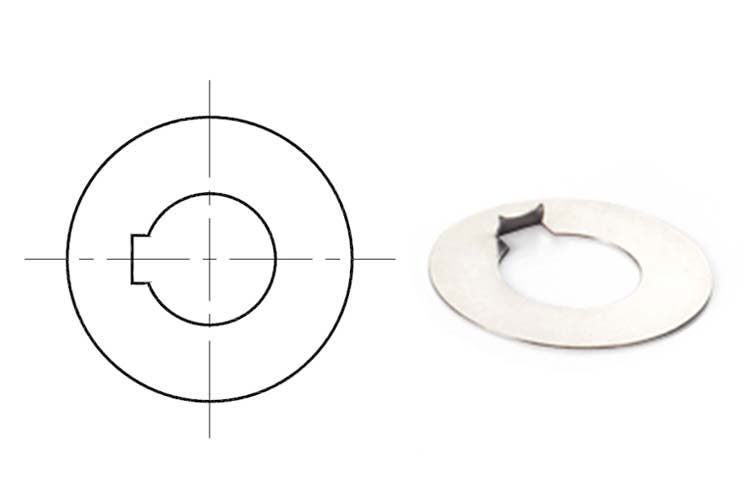

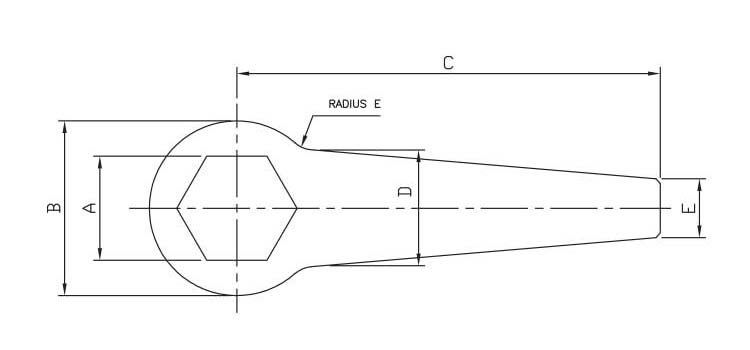

Cone Nut Spanner

MATERIAL - MILD STEEL

| SPANNER CODE |

A/F |

LENGTH B |

THICKNESS |

| CSMS300 |

1.75” |

7” |

0.375” |

| CSMS400 |

2.63” |

9” |

0.375” |

| CSMS476 |

3.15” |

11” |

0.500” |

| CSMS576 |

3.89” |

13” |

0.500” |

| CSMS676 |

4.85” |

14” |

0.750” |

| CSMS776 |

5.25” |

15” |

0.750” |

| CSMS876 |

6.00” |

16” |

1.000” |

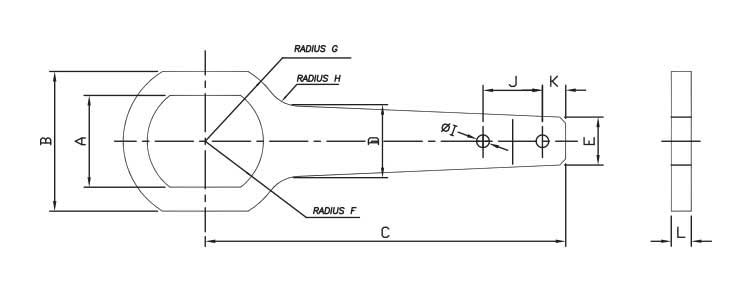

Hex Nut

MATERIAL - MILD STEEL 1

| HEX NUT CODE |

IMPERIAL SHAFT DIA |

METRIC SHAFT DIA |

THREAD A |

A/F E |

FLANGE DIA D |

| HNMG 80 |

3.14” |

80MM |

M56 X 3 |

80 |

117 |

| HNMG 90 |

3.50” |

90MM |

M56 X 3 |

100 |

127 |

| HNMG 100 |

4” |

100MM |

M56 X 3 |

100 |

152 |

Hex Nut Spanner

MATERIAL - MILD STEEL

| SPANNER CODE |

A/F |

LENGTH B |

THICKNESS |

| HSMS80 |

80 |

180 |

16 |

| HSMS90 |

100 |

180 |

16 |

| HSMS100 |

100 |

180 |

16 |

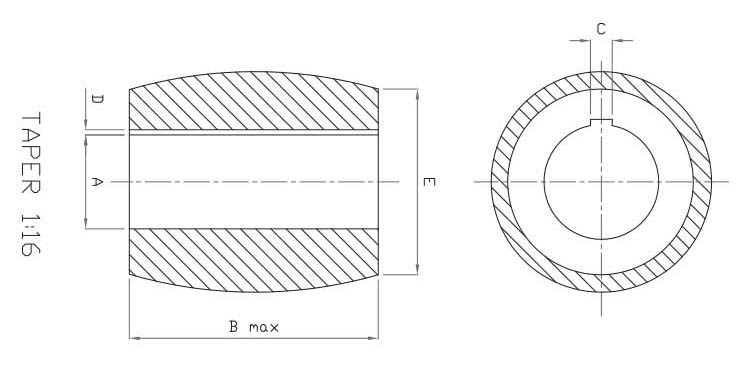

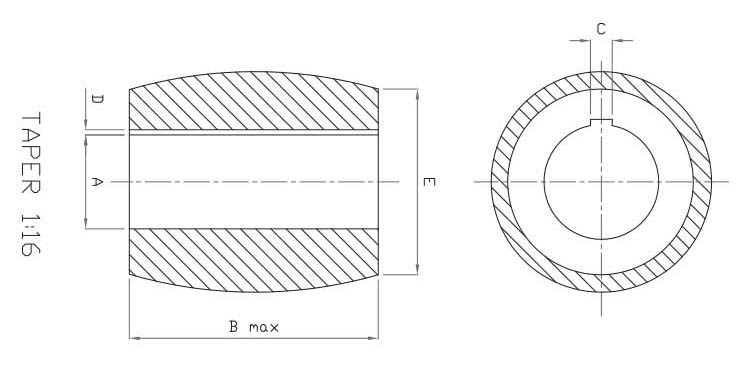

Hub Bore Dimension

SAE Standard Tapers:

NOTES:

- Shaft & bores to 6" & diameter have taper of ¾"/ft. on the diameter 1/16"/inch 1 degree 47'23" angle with centerline.

- Shaft and bores 6" and larger have taper of 1"ft. on diameter.

- For intermediate size, refer to SAE handbook or contact us.

- Propeller hub length generally is less than maximum "B".

PROPELLER HUB TAPER 1:16

| Standard Taper |

Dia. Small End (A) |

Hub Length (B) |

Moninal Keyway (D) |

Width (C) |

Depth (D) |

| ¾” |

0.608 |

0.410 |

2-1/4” |

3/16” |

3-32” |

| 7/8” |

0.710 |

0.712 |

2-5/8” |

¼” |

1/8” |

| 1” |

0.811 |

0.813 |

3” |

¼” |

1/8” |

| 1-1/8” |

0.913 |

0.915 |

3-3/8” |

¼” |

1/8” |

| 1-1/4” |

1.015 |

1.017 |

3-3/4” |

5/16” |

5/32” |

| 1-3/8” |

1.116 |

1.118 |

4-1/8” |

5/16” |

5/32” |

| 1-1/2” |

1.218 |

1.220 |

4-1/2” |

3/8” |

3/16” |

| 1-3/4” |

1.421 |

1.423 |

5-1/4” |

7/16” |

7/32” |

| 2” |

1.624 |

1.626 |

6’’ |

½” |

¼” |

| 2-1/4” |

1.827 |

1.829 |

6-3/4” |

9/16” |

9/16” |

| 2-1/2” |

2.030 |

2.032 |

7-1/2” |

5/8” |

5/16” |

| 2-3/4” |

2.233 |

2.235 |

8-1/4” |

5/8” |

5/16” |

| 3” |

2.437 |

2.439 |

9” |

¾” |

5/16” |

| 3-1/4” |

2.640 |

2.642 |

9-3/4” |

¾” |

5/16” |

| 3-1/2” |

2.843 |

2.845 |

10-1/2” |

7/8” |

5/16” |

| 3-3/4” |

3.046 |

3.048 |

11-1/4” |

7/8” |

5/16” |

| 4” |

3.249 |

3.251 |

12” |

1” |

1” |

| 4-1/2” |

3.796 |

3.798 |

11-1/4” |

1-1/8” |

3/8” |

| 5” |

4.218 |

4.220 |

12-1/2” |

1-1/4” |

7/16” |

| 5-1/2” |

4.640 |

4.642 |

13-3/4” |

1-1/4” |

7/16” |

| 6” |

4.749 |

4.751 |

15” |

1-3/8” |

½” |

| 6-1/2” |

5.145 |

5.147 |

16-1/4” |

1-3/8” |

½” |

| 7” |

5.541 |

5.543 |

17-1/2” |

1-1/2” |

9/16” |

| 7-1/2” |

5.937 |

5.939 |

18-3/4” |

1-1/2” |

9/16” |

| 8” |

6.332 |

6.334 |

20” |

1-3/4” |

9/16” |

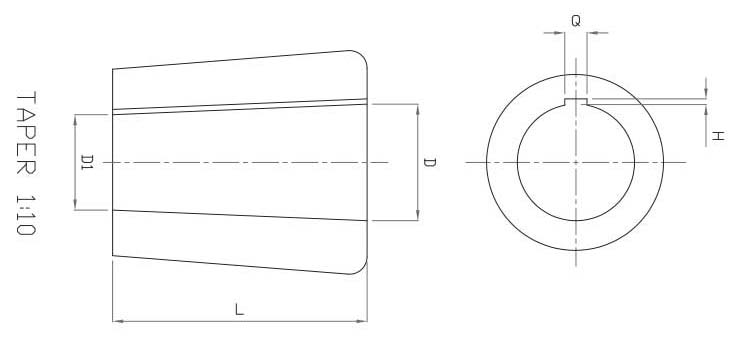

PROPELLER HUB TAPER 1:10

| Shaft Dia. |

Big Dia.D |

Small D 1 |

Length L |

B |

Keyway |

| 20 |

20 |

15 |

50 |

6 |

3 |

| 25 |

25 |

19 |

60 |

6 |

3 |

| 30 |

30 |

22 |

70 |

8 |

4 |

| 35 |

35 |

26 |

80 |

10 |

4 |

| 40 |

40 |

30 |

90 |

12 |

4 |

| 45 |

45 |

34 |

100 |

14 |

5.5 |

| 50 |

50 |

38 |

120 |

14 |

5.5 |

| 55 |

55 |

42 |

130 |

16 |

5.5 |

| 60 |

60 |

46 |

140 |

16 |

5.5 |

| 65 |

65 |

50 |

150 |

18 |

5.5 |

| 70 |

70 |

54 |

160 |

18 |

5.5 |

| 75 |

74.5 |

57.5 |

170 |

20 |

6 |

| 80 |

79.5 |

61.5 |

180 |

20 |

6 |

| 85 |

84.5 |

65.5 |

190 |

22 |

7 |

| 90 |

89.5 |

69.5 |

200 |

22 |

7 |

| 95 |

94.5 |

73.5 |

210 |

25 |

7 |

| 100 |

99 |

77 |

220 |

25 |

7 |

| 110 |

109 |

85 |

240 |

28 |

7.5 |

| 120 |

119 |

93 |

260 |

32 |

8.5 |

| 130 |

129 |

101 |

280 |

36 |

9.5 |

| 140 |

139 |

109 |

300 |

36 |

9.5 |

| 150 |

149 |

117 |

320 |

36 |

9.5 |

| 160 |

159 |

125 |

340 |

40 |

10.5 |

Chemical Composition (%)

| Casting Grade |

Cu |

Al |

Mn |

Zn |

Fe |

Ni |

Sn |

Pb |

P |

| Cu1 |

52-62 |

0.5-3 |

0.5-4.0 |

35-40 |

0.5-2.5 |

Max 1.0 |

0.1-1.5 |

Max 0.5 |

|

| Cu2 |

50-57 |

0.5-2 |

01-4.0 |

33-38 |

0.5-2.5 |

3.0-8.0 |

Max 1.5 |

Max 0.5 |

|

| Cu3 |

77-82 |

7.0-11 |

0.5-4.0 |

Max 1.0 |

2.0-6.0 |

3.0-6.0 |

Max 0.1 |

Max 0.03 |

|

| Cu4 |

70-80 |

6.5-9.0 |

8.0-20 |

Max 6.0 |

2.0-5.0 |

1.5-3.0 |

Max 1.0 |

Max 0.05 |

|

| Gunmetal |

83,0 - 87,0 |

— |

— |

4,0 - 6,0 |

— |

2,0 max |

4,0 - 6,0 |

4,0 - 6,0 |

0,10 max |

| Casting Grade |

Proof Stress Rp0.2 [N/mm2] min. |

Tensile Strength Rm0.2 [N/mm2] min |

ElongationA5 [%] min. |

| Cu1 |

175 |

440 |

20 |

| Cu2 |

175 |

440 |

20 |

| Cu3 |

245 |

590 |

16 |

| Cu4 |

275 |

630 |

18 |

| Gunmetal |

90 |

200 |

13 |

Imperial

| Grade of Steel |

1% Proof stress N/mm2) minimum |

Tensile strength (N/mm2) minimum |

Elongation % |

| 304 |

210 |

485 |

40 |

| 316 |

210 |

485 |

40 |

| Duplex UNS S31803 |

245 |

620 |

25 |

| Duplex UNS S32750 |

245 |

795 |

15 |

Imperial

| Grade of Steel |

C% Max |

Mn% Max |

Si% Max |

S% Max |

P% Max |

Cr% Max |

Ni% Max |

Mo% Max |

| 304 |

0.08 |

2.00 |

1.00 |

0.030 |

0.045 |

18-20 |

8-11 |

| 316 |

0.08 |

2.00 |

1.00 |

0.030 |

0.045 |

16-18 |

10-14 |

2-3 |